EDI Receives Patent For Flat-Die Design

Chippewa Falls, WI - Extrusion Dies Industries, LLC (EDI) has been granted US. Patent No. 7,056,112 B2 for a flat-die design that reduces the downtime for lip adjustment required with each new product run, enhances gauge profiles, and yields a uniform layer structure in coextrusion, the company announced recently. Tradenamed Contour Die, the innovative system is now in commercial film and sheet production worldwide.

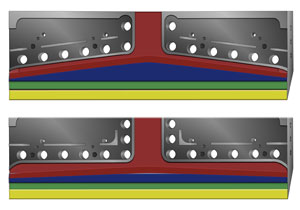

The Contour Die solves a longstanding problem caused by the pressure of the molten polymer in the manifold or flow channel between the bodies, or halves, of any flat die. This pressure (in the range of 1,000 to 3,000 p.s.i., or 70 to 200 BAR) is great enough to deflect the heavy steel bodies. In conventional dies, because the surface area that is "wetted," or in contact with molten polymer, is greater at the center than at the ends, the result is non-uniform deflection; this in turn causes a product distortion commonly called "clamshelling." While it is possible to correct the problem with the lip-adjustment systems that are standard on flat dies, the frequent adjustments required when there are many small-run jobs cause a substantial loss in productivity. The problem is even more serious in coextrusion, since lip adjusters cannot correct the distortions at the interface between layers.

"Understanding the phenomenon of die deflection enabled us to address both of these issues," said Contour Die inventor John A. Ulcej, EDI's executive vice president of engineering and technology. "Ultimately we solved the problem of non-uniform deflection by designing a die that is very different in appearance from the block-like conventional die."

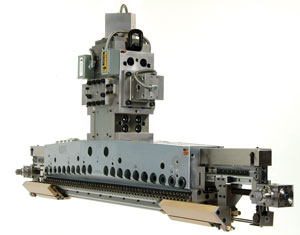

The Contour Die has a unique tapered or "sculpted" shape: thicker in the center, where the bending force is greater, than at the ends (see photo). This design enables EDI to retain the triangle-shaped "coat hanger" manifold that is widely used in the industry because it promotes a streamlined flow of molten polymer through the die (see schematic).

"Previous ‘constant-deflection' dies built by EDI and others dispensed with the coat hanger manifold in favor of a ‘broad shoulders' manifold with a straight back wall parallel to the die exit," said Ulcej. "This produced uniform die body deflection, but with a sacrifice in streamlining. The corners at either end of the back wall constituted dead spots where low-velocity flow or polymer hang-up could cause degradation, manifested in the finished product as gels, pinholes, and other defects."

Another benefit of streamlined flow is a reduction in the time needed to purge the die for color or resin changes. At the same time, Ulcej noted, the combination of uniform die body deflection and streamlined flow provides greater leeway for increasing extruder throughput without compromising product quality.

SOURCE: EDI